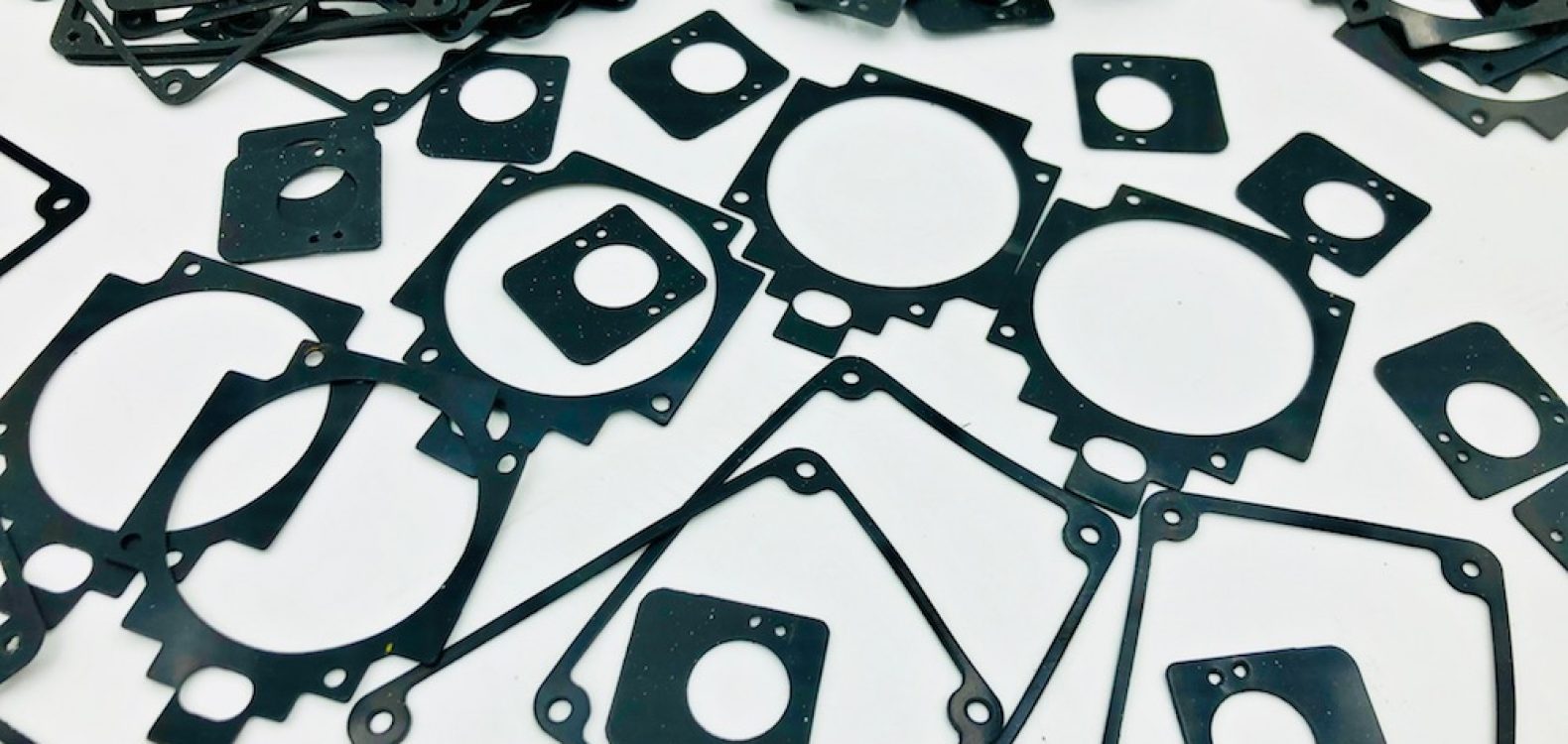

Custom EPDM gaskets factory. EPDM (Ethylene Propylene Diene Monomer) rubber gaskets are essential components used in various industries for sealing, insulation, and vibration control. A factory dedicated to manufacturing custom EPDM rubber gaskets plays a vital role in meeting the specific needs of diverse applications.

Factory Location and Infrastructure: A custom EPDM rubber gaskets factory typically operates in an industrial area with easy access to transportation and raw materials. The factory’s infrastructure is designed to meet the highest industry standards for safety, quality, and efficiency. It includes:

- Production Area: This is the heart of the factory where the gaskets are manufactured. It is equipped with specialized machinery, including extruders, presses, and cutting equipment, to process EPDM rubber sheets.

- Quality Control Laboratory: To ensure the gaskets meet rigorous quality standards, the factory has a dedicated lab equipped with testing equipment for material analysis, dimensional accuracy, and performance testing.

- Raw Material Storage: EPDM rubber comes in various forms, including sheets and rolls. The factory has storage facilities to house these materials in a controlled environment to maintain their integrity.

- Tooling and Mold Workshop: Custom EPDM gaskets often require specialized tooling and molds. The factory has a workshop for designing and manufacturing these tools.

Production Process: The production of custom EPDM rubber gaskets involves several steps:

- Material Selection: The factory selects the appropriate EPDM rubber compound based on the gasket’s intended application. This compound may vary in terms of hardness, resistance to temperature, chemicals, and UV exposure.

- Material Preparation: EPDM rubber sheets are cut or extruded into the desired shape and size.

- Molding and Pressing: The cut or extruded rubber is placed into molds and subjected to heat and pressure, which vulcanizes the rubber, giving it its final shape and properties.

- Secondary Operations: Depending on the requirements, secondary operations such as cutting, punching, drilling, and adhesive application are performed to customize the gaskets.

- Quality Control: Every batch of gaskets undergoes rigorous quality control checks to ensure they meet the specified tolerances, durability, and sealing capabilities.

Customization Capabilities: A specialized EPDM rubber gaskets factory can produce gaskets tailored to meet specific customer needs. This customization may include:

- Size and Shape: Gaskets can be produced in a wide range of sizes and shapes to fit unique applications.

- Material Properties: EPDM rubber compounds can be formulated to meet specific requirements, such as temperature resistance, chemical resistance, and electrical conductivity.

- Tolerances: The factory can manufacture gaskets with tight tolerances to ensure a precise fit.

- Surface Finish: Gaskets can be customized with various surface finishes, such as smooth, textured, or adhesive-backed, depending on the application.

Quality Assurance: Quality is paramount in a custom EPDM rubber gaskets factory. Quality assurance measures include:

- ISO Certification: The factory typically holds ISO 9001 certification, ensuring adherence to quality management standards.

- Batch Testing: Each batch of gaskets undergoes comprehensive testing to verify their performance and durability.

- Traceability: Traceability systems track the origin of raw materials and the production process for quality control and accountability.

- Customer Feedback: Customer feedback is actively sought and incorporated into the continuous improvement process.

Environmental Responsibility: Many modern factories are committed to environmentally responsible practices. This includes recycling and waste reduction initiatives, energy-efficient processes, and compliance with environmental regulations.

Conclusion: A custom EPDM rubber gaskets factory is a sophisticated facility that combines advanced manufacturing processes with customization capabilities to provide high-quality gaskets for a wide range of industrial applications. These factories are essential for industries that rely on reliable sealing solutions to maintain the integrity of their products and processes.