Custom EPDM gaskets play a crucial role in various industries and applications due to their exceptional properties and versatility. EPDM, which stands for Ethylene Propylene Diene Monomer, is a synthetic rubber known for its outstanding resistance to weathering, ozone, UV radiation, and extreme temperatures, making it an ideal choice for gaskets designed to withstand harsh environmental conditions.

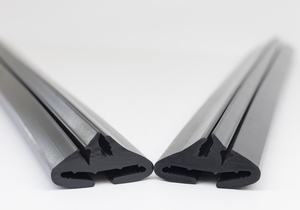

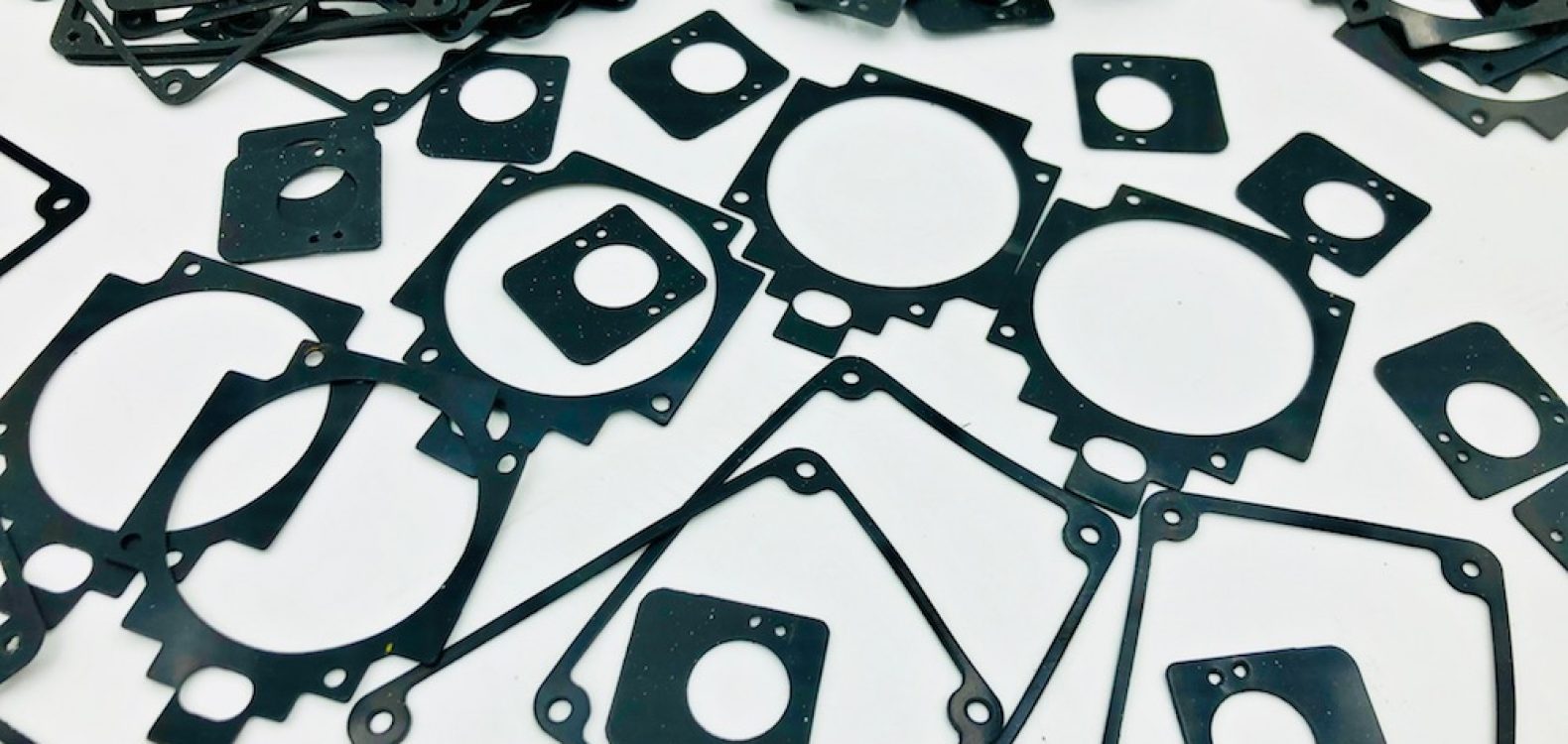

These gaskets are highly customizable to meet specific requirements and can be tailored to various sizes, shapes, and thicknesses. Whether you need a small, intricate gasket for a precision instrument or a large, robust gasket for industrial machinery, EPDM rubber can be formulated and manufactured to your exact specifications.

Some key features and benefits of custom EPDM rubber gaskets include:

- Weather Resistance: EPDM rubber gaskets are highly resistant to weathering, making them suitable for outdoor applications where exposure to sunlight, rain, and temperature fluctuations is common. This resistance ensures long-term durability and prevents cracking, splitting, or degradation over time.

- Chemical Resistance: EPDM rubber is known for its resistance to a wide range of chemicals, including acids, bases, and solvents. This makes EPDM gaskets suitable for use in chemical processing, automotive, and industrial settings where exposure to various substances is a concern.

- Temperature Stability: EPDM gaskets can perform reliably in extreme temperature conditions, from -50°C to 150°C (-58°F to 302°F). This versatility makes them suitable for both cold and hot applications.

- Excellent Sealing Properties: EPDM rubber gaskets exhibit excellent compression set characteristics, ensuring they maintain their shape and sealing properties even under prolonged compression. This feature is crucial for preventing leaks and maintaining a secure seal in various applications.

- UV and Ozone Resistance: The resistance of EPDM rubber to UV radiation and ozone makes it an excellent choice for outdoor and automotive applications, where prolonged exposure to sunlight and environmental elements is common.

- Electrical Insulation: EPDM rubber also has good electrical insulation properties, making it suitable for use in electrical enclosures and applications where electrical conductivity must be minimized.

- Customization: EPDM gaskets can be customized to meet specific requirements, including varying durometers (hardness levels), colors, sizes, and shapes. This customization ensures that the gaskets meet the precise needs of your application.

- FDA Approval: Certain EPDM formulations are FDA-compliant and suitable for use in food and beverage processing equipment, ensuring product safety and regulatory compliance.

- Easy Installation: EPDM rubber gaskets are typically easy to install and can be fitted into various grooves, flanges, or mating surfaces with minimal effort.

Applications of custom EPDM rubber gaskets are diverse and include automotive seals, HVAC systems, electrical enclosures, outdoor equipment, marine applications, industrial machinery, and more. Their ability to withstand extreme conditions while providing a reliable seal makes them an indispensable component in many industries.

In conclusion, custom EPDM rubber gaskets offer a wide range of advantages, making them a top choice for sealing and gasketing solutions across multiple industries. Their durability, resistance to environmental factors, chemical compatibility, and customization options make them an invaluable asset for engineers and manufacturers seeking dependable sealing solutions for their unique applications.